On an average day, women and children in Africa take multiple trips to find to any available water. While a water source may be available, the water that is found may not always be potable. This 2-in-1 cart solution, allows for the filtration and transportation of water over flat lands in order to reduce trips made to water sources and spinal injury.

Research and Observations

Water is a resource that is commonly taken for granted in the developed world, however, for many people, it is not easily accessible. Globally, 748 million people lack access to drinking water and 1.8 billion people use water that is faecally contaminated as a source of drinking water (GLAAS, 2014), 37% of these people live in Sub-Saharan Africa (The Water Project). For people in Sub-Saharan Africa, getting the water necessary for daily activities such as cooking, cleaning, bathing and farming is not as easy as turning on a tap. On average, they travel 2 to 10 kilometers to get to water collection points and this trip has to be made multiple times a day making the simple task of getting water consume 3 to 9 hours a day (Hippo Roller). Water collection is not only time consuming process, it is also physically difficult. Water itself is very heavy, weighing 8.35 pounds per gallon. The current method for water transportation involves filling up a bucket with water and carrying it on one's head. These buckets have an average weight of 44 pounds (waterinfo.org) and over time this causes significant stress on the neck and spine and causes long term injuries. This method of water transportation also does not provide any kind of filtration and the open containers allow the water to be further contaminated once it is brought back.

Did you know that on average, women and children in Africa:

Transport water an average

distance of 3.7 miles...

Take multiple trips per day

to a water source...

Carry an average of 44 lbs of

water on their head...

Conceptualization and Concept Sketches

First concept design for filtration cart showing filter within "rubbermaid" with small wheels

Filtration cart concept with water filtering through axles and into wheels

Second concept design focusing on filter design and introducing the idea of using wheels to store water

Articulated cart concept for ease on motion

Third concept design features a PVC frame cart the rolls on water drums

Initial water filtration design filters water through a water jug

Prototype Testing

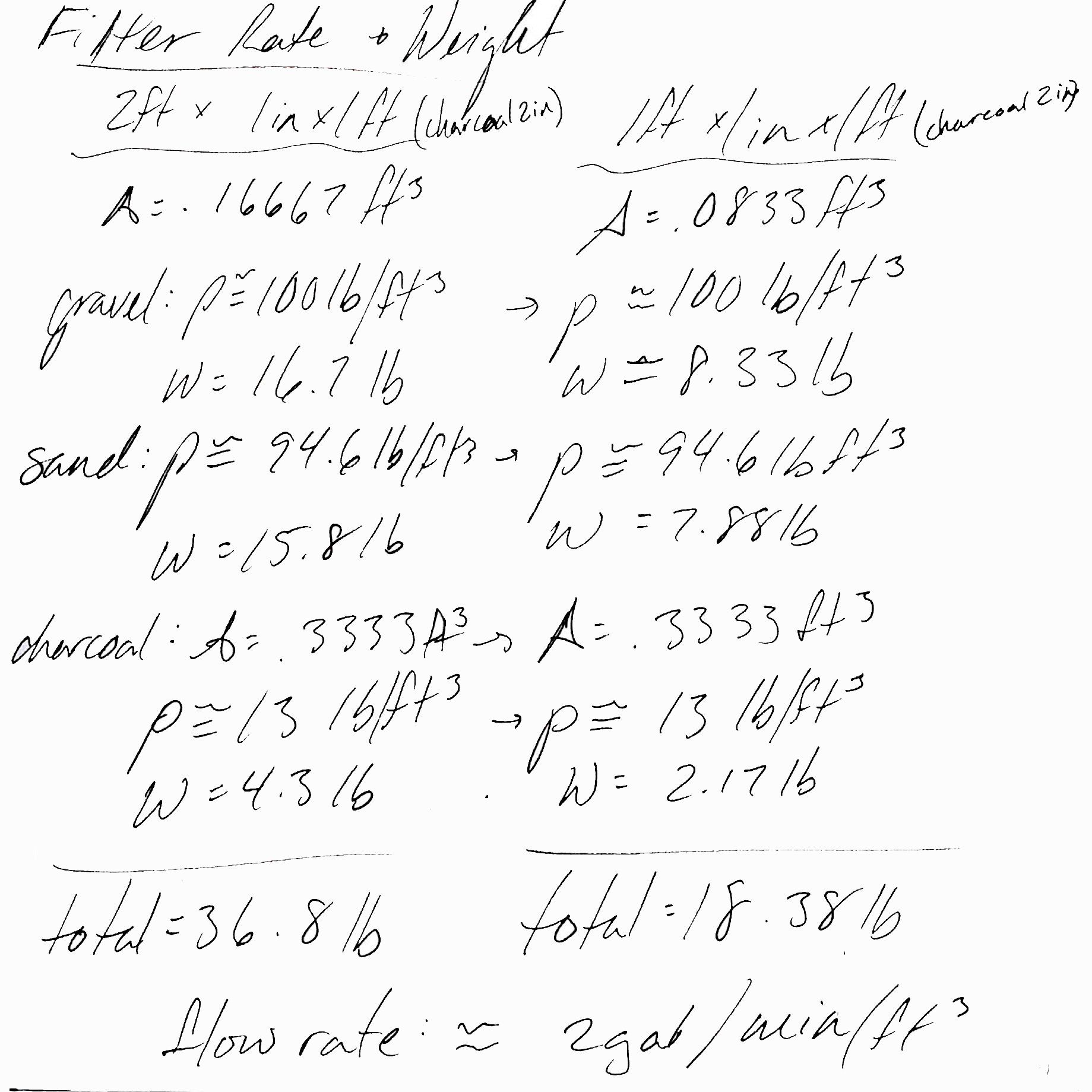

Testing was done individually on each individual subsystem in order to ensure that each part worked before testing together. Below is the testing for the filtraton system. Flow rate was maximized while keeping the overall weight of the material to a minimum.

Filter design in bucket showing layered materials separated by mesh

Calculations for filter flow rate and weight

Prototype Fabrication

In designing the final product, wood was used to create the body of the cart. The wheels were made of food-safe plastic and attached to the cart using steel for the axles. A bio filter was placed on top of the cart while a pump aided in moving water from the source to the filter.

This project was created in collaboration with several other students for Intro to Engineering Design in Spring of 2016.